|

| my first ship |

How are Containers stored Onboard Ships?

This facilitates maximum use of cargo spaces in container ships.

It is interesting to know that the containers are of two different sizes:

Their sizes are defined in terms of EU(Equivalent Units) which is international standard for the container ships and port terminal facilities to standardize their use world wide.

- FEU (Fourty Equivalent Unit).Its dimensions are 40 feet x 8 feet x 8 feet.One FEU is equivalent to 25 metric tons or 72 cubic meters if filled with water.

- TEU (Twenty Equivalent Unit). Its dimensions are 20 feet x 8 feet x 8 feet (8.6 feet precisely).

- Corner Post: Vertical frame components located at the corners of freight containers and integral with the corner castings and floor structures.

- Corner Castings: Fittings located at the corner of the freight container which provide means for lifting, handling, stacking and securing the container.

- Header and Sill: In way of door entrance with overhead horizontal header frame and similar floor level threshold sill.

- Front-End Frame: The structure at the front end of the container (opposite the door end) consisting of top and bottom rails attached to the front corner posts and the corner castings.

- Top Rail: Longitudinal structural members located at the top edge on either side of the freight container.

- Bottom Rail: Longitudinal structural members located at the bottom edge on either side of the freight container.

- Cross-members: A series of transverse beams at approximately 12 inch centers attached to the bottom side rail and an integral part of the floor frame support.

- Floor: The floor may be hard or soft laminated wood, planks or plywood.

- Roof: Roof bows are the undermost structure of the roof and are usually placed at 18 or 24 inch centers. Modern steel GP containers (except open top containers) are not fitted with roof bows but will have corrugated or flat steel sheet roofs welded to the frame members.

- Aluminum containers have aluminum sheathing, bonded with adhesive to the roof bows and riveted to the top rails and headers. GRP containers have fiberglass reinforced plywood panels fastened to the rail and headers. The roof is the part of the container most vulnerable to damage.

- Sides & Front: Modern steel GP containers will have corrugated steel panels. Aluminum containers have aluminum sheathing on the sides and front of the container which are affixed to aluminum stringers which are in turn bolted to the top and bottom rails and also to the front end frame. The stringers may be on the outside or inside of the sheathing. GRP containers do not use stringers for supporting the fiberglass reinforced plywood panels. The side and the front of steel containers are made of corrugated steel sheets eliminating stringers.

- Doors: Doors may be ply-metal (plywood core with steel or aluminum facings), corrugated, or combinations with fiberglass. The hinged doors have plastic or rubber lined door gaskets as seals against water ingress.

- Security seal: Used in conjunction with locking mechanism in order to seal the containers for security purposes. These seals are numbered and often color coded.

These containers are lifted at terminals through huge gantries which are basically human operated elevated cranes which speedily stow the containers on and off the ship's hatches.

These containers are lifted at terminals through huge gantries which are basically human operated elevated cranes which speedily stow the containers on and off the ship's hatches.A reach stacker is a vehicle used for handling intermodal cargo containers in small terminals or a medium-sized ports. Reach stackers are able to transport a container short distances very quickly and pile them in various rows depending on its access.

See the Picture below.The green coloured structure is a Gantry!

|

|

|

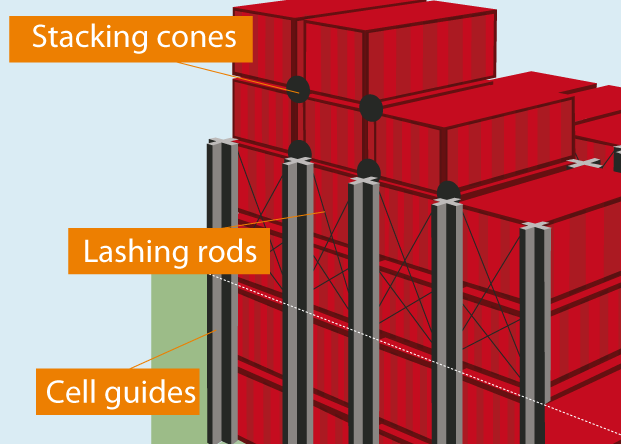

When the container is stowed inside the cargo hold, it is directed and secured against moving by the CELL GUIDES. These guides help the container to be stored intact throughout.

When the container is stowed inside the cargo hold, it is directed and secured against moving by the CELL GUIDES. These guides help the container to be stored intact throughout.LASHING

Defined as linking device used to secure and fasten two or more items together in a somewhat rigid manner.

It is a key for a safe ship as it keeps the containers stacked in secure manner even when ship is experiencing heavy dynamic movements.

Lashing Equipment

Turnbuckles.

Turnbuckles are used for tensioning a ship's rigging and lashings. This device is also known as a bottlescrew in this context.

Twist Locks.

A twistlock and corner casting together form a standardised rotating connector for securing shipping containers. The primary uses are for locking a container into place on container ship, semi-trailer truck or railway container train; and for lifting of the containers by container cranes and sidelifters.

Handing Stracker.

READ ADVANCED PROCEDURES ABOUT CONTAINER STOWAGE HERE:

Extension Rods.

Help to extend the span of turnbuckle.

Twist Locks.

A twistlock and corner casting together form a standardised rotating connector for securing shipping containers. The primary uses are for locking a container into place on container ship, semi-trailer truck or railway container train; and for lifting of the containers by container cranes and sidelifters.

Handing Stracker.

READ ADVANCED PROCEDURES ABOUT CONTAINER STOWAGE HERE:

IF YOU LIKE MY WORK THEN SHARE THE HAPPINESS WITH OTHERS!

0 comments:

Post a Comment

Spark your idea here!